Underfloor heating network

An underfloor heating network is established during the finishing phase, as there must be several conditions before implementation, including

The floor should be level and there should be no obstacles

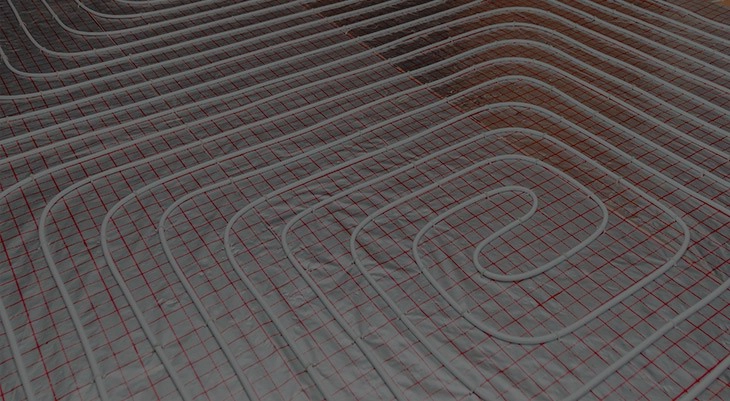

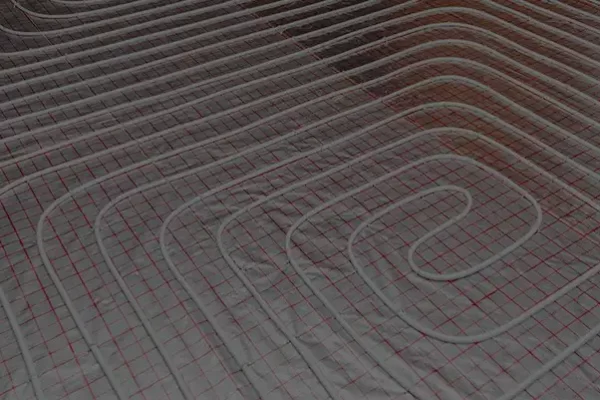

Stages of project implementation: The blue foam material with the highest density is distributed throughout the places to be heated, then the reflector is placed to reflect the heat upwards, then we run the pipes on the reflector layer, and then we install the pipes with foam using special clips, and then we collect all the pipes inside The assembly panel for heating, and then we put a wall insulation to prevent the escape of heat through the walls, and then we cover the pipes with a thin cement layer to maintain the integrity of the pipes, knowing that the pipes consist of 5 layers, including the aluminum layer, and the pipe diameter is 16 mm

The distance between one pipe and the other is determined based on the calculation of loads. For example, in some places, the distance between one pipe and the other is 10 cm, 15 cm in places, and 20 cm in places. The way the pipes run is determined after conducting a specific study for each space separately inside the house.

And after the completion of the final finishing stage, a digital thermostat is installed to control the room temperature according to demand (bearing in mind that in each room there is a thermostat to control the temperature)